Visit our QuantEnergo LiFePO4 battery online store. Shop now >

INDUSTRIAL AND COMMERIAL AIR PURIFICATION SYSTEM

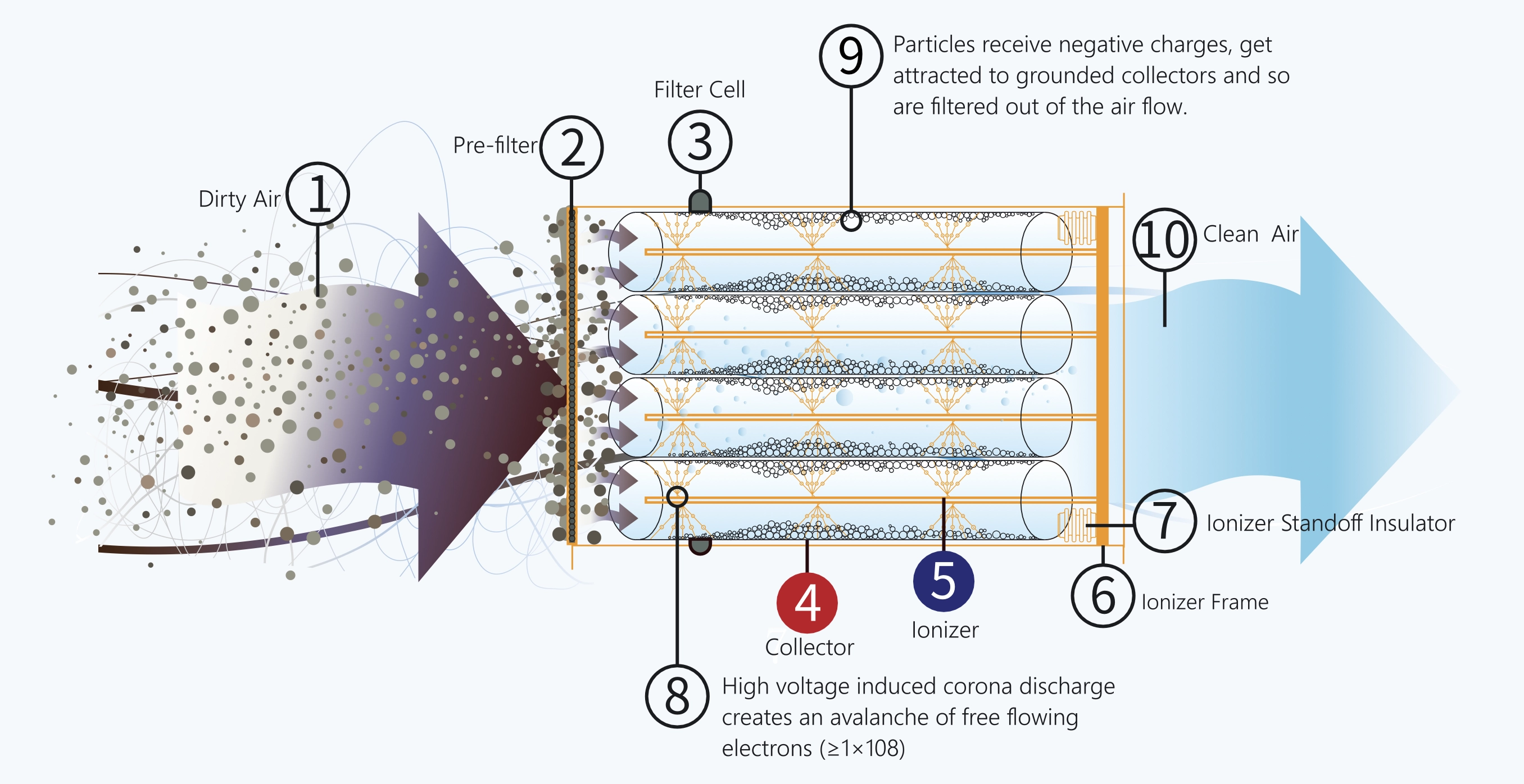

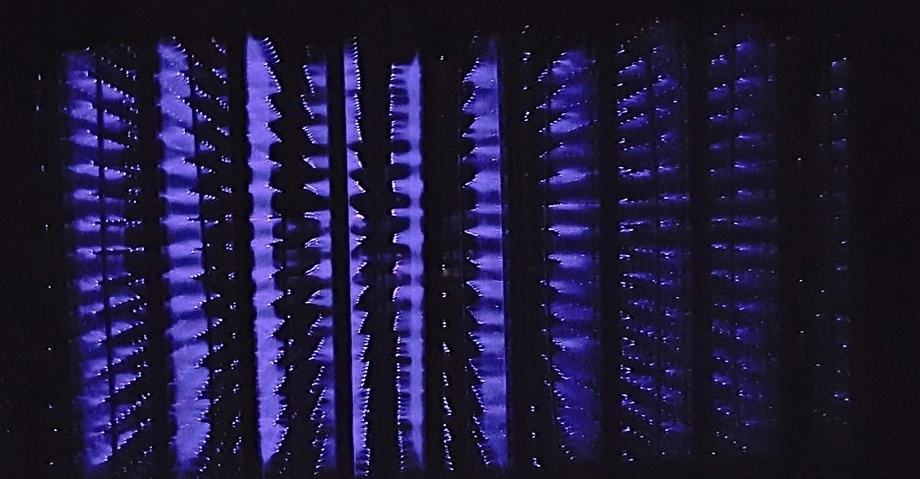

Plasma-Catalytic Static Air Purification system for smoke gases of any origin, including automobile exhaust, smoke gases from incineration plants, coal and oil power plants, hazardous industrial and commercial enterprises, restaurant smoke odours and oily aerosols generated during cooking. The plasma-catalytic filter is a high-voltage cold plasma flow reactor, in which a strong pulsed electrostatic field with high energy concentration is created by means of a corona avalanche barrier discharge. When a contaminated air flow passes through the interelectrode gap, the energy of an avalanche corona discharge of high energy density and high intensity destroys molecules of volatile organic compounds, including toxic dioxins and furans. Molecules are broken down into elementary constituent chemical elements. Also, the corona avalanche discharge generates intense radiation of the ultraviolet spectrum, which also contributes to the destruction of dangerous molecules and the sterilization of the environment. Water moisture or water vapor under these conditions forms highly reactive oxidative radicals known as reactive oxygen species (ROS) and hydroxyl group (OH°) radicals and triatomic oxygen O3 (ozon).

THIS EXTREMELY HIGH-ENERGY REACTIVE MEDIUM OXIDIZES, DISSOLVES AND DECOMPOSES VIRTUALLY ALL KNOWN ORGANIC AND CHEMICAL MOLECULES AND CLUSTERS INTO ELEMENTAL CHEMICAL ELEMENTS.

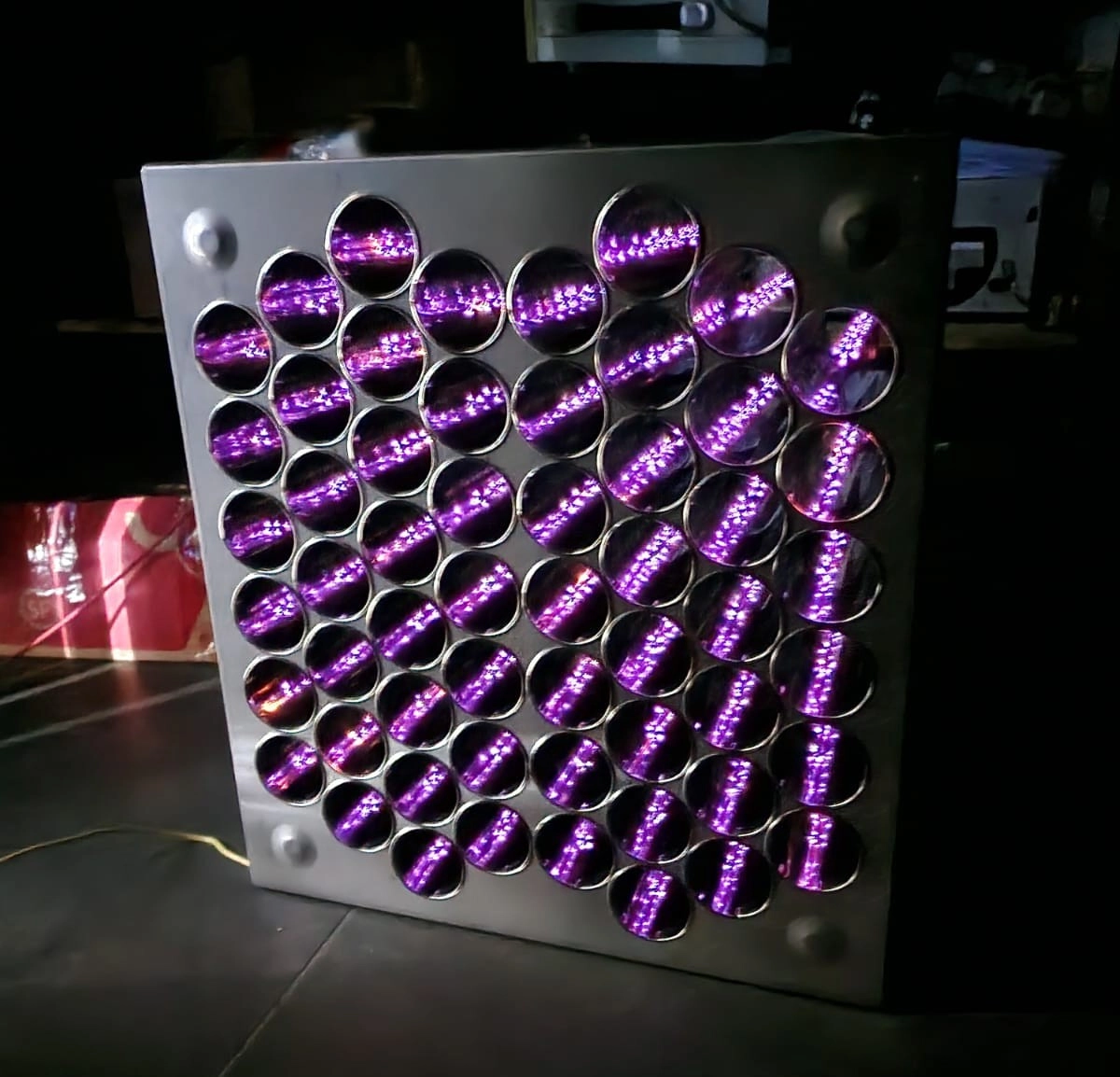

Cold Plasma Corona Discharge process

The special design and geometry of the reactor makes it possible to create an intense multi-layered plasma cloud. When smoke gases pass through the cloud, they, as well as especially dangerous furans and dioxins, are completely destroyed. The recommended system configuration contains a minimum of three serial blocks.

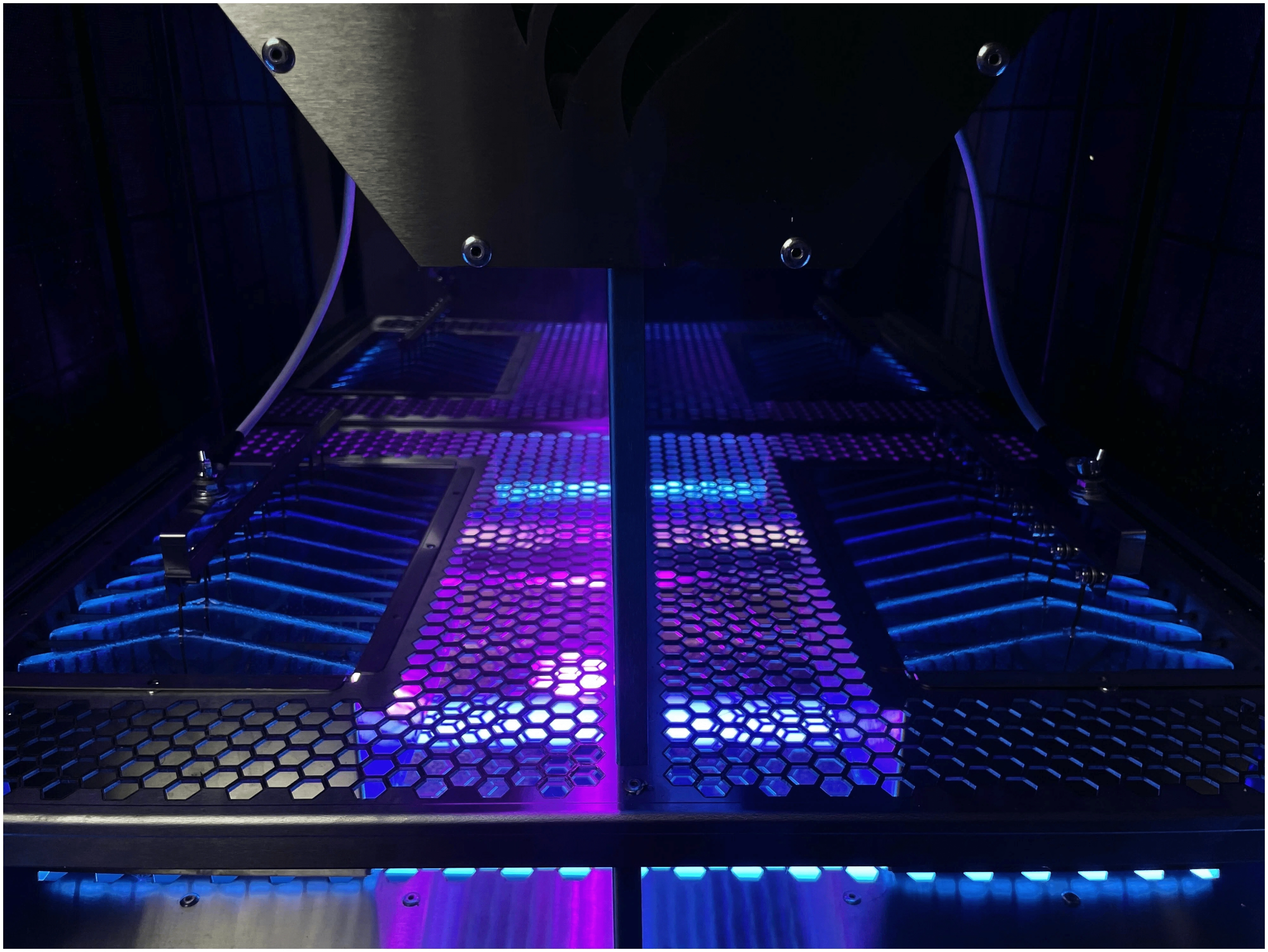

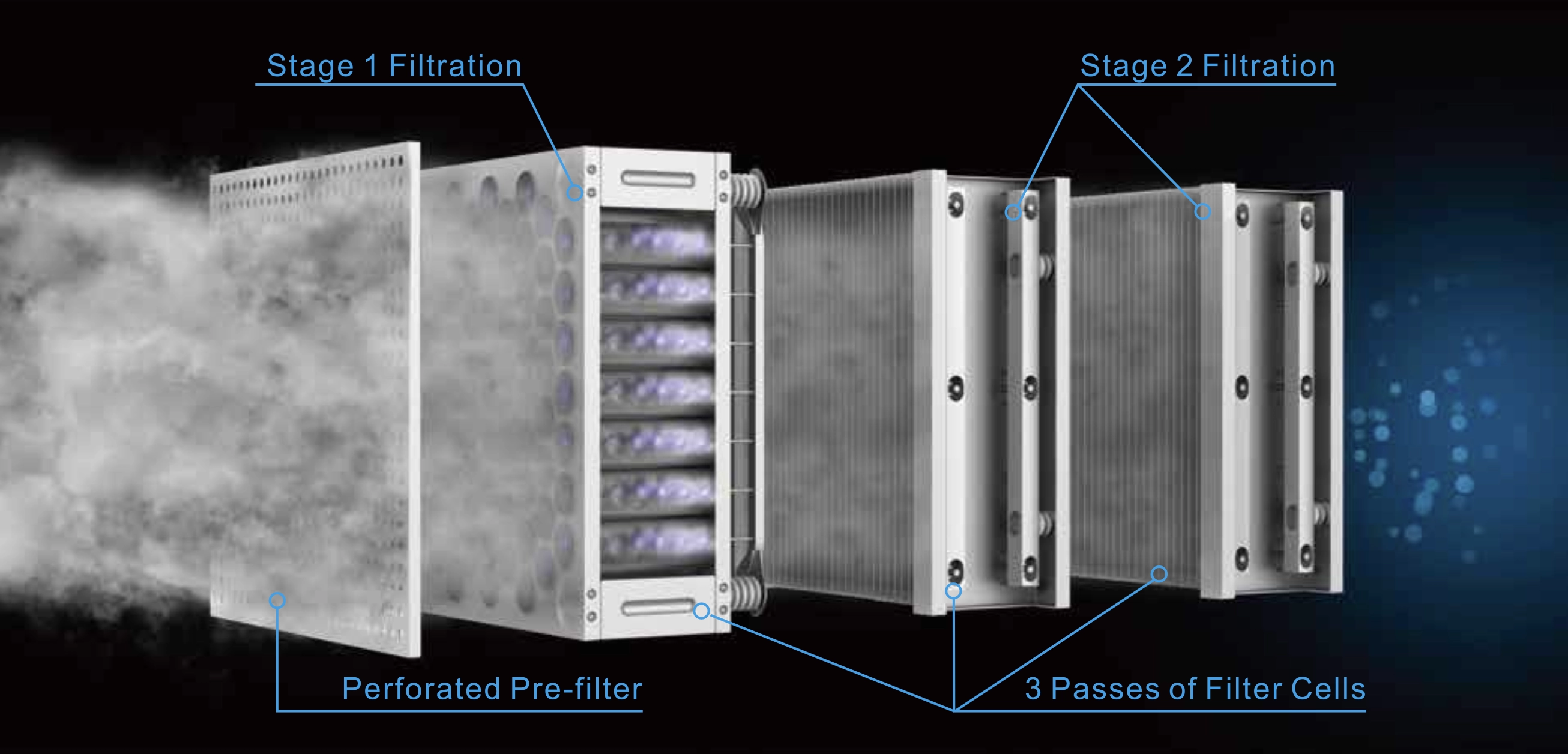

PLATE FILTER SYSTEM

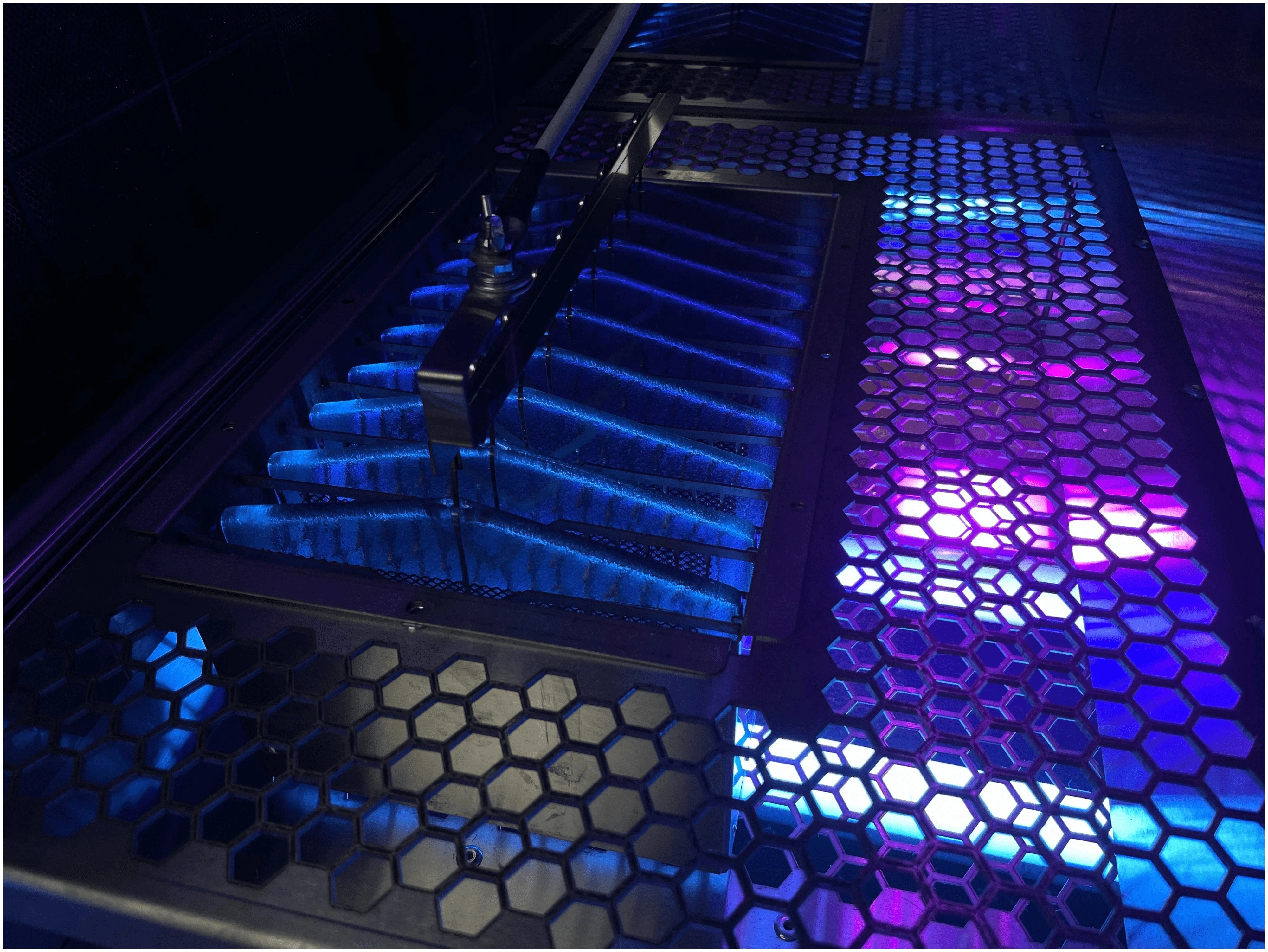

TUBULAR (HONEYCOMB) FILTER SYSTEM

COLD PLASMA FILTER (CPF) PROCESS

Block 1 is a Pre-filter designed to trap large soot particles and oil aerosols. The Pre-filter is a multi-layered bag of fine honeycombed corrugated metal mesh, packed in a cassette with a thickness of 50 to 100 mm. If this filter is contaminated beyond the permissible level, it must be washed with ordinary detergents.

Block 2 of the Plasma block, under the action of high voltage from 16 to 30.000 Volts, creates a volumetric field of "cold plasma of the corona avalanche discharge". Smoke gas emissions are completely destroyed and oxidized by ozone and OH hydroxyl radicals, which are formed as a result of the interaction of the resonance of a high-voltage corona discharge and moisture vapor.

Block 3 is designed for Static collection of the particles destroyed in the plasma reactor. By applying a high-voltage bipolar voltage to the trapping electrode plates, the system splits and deposits the residual amounts of gaseous emission particles. During maintenance it is easily washed in manual or automatic mode. Block 3 can be used before or after the Plasma block.

An additional Carbon filter can be used for our system. The whole system can be made for domestic, commercial and industrial applications.

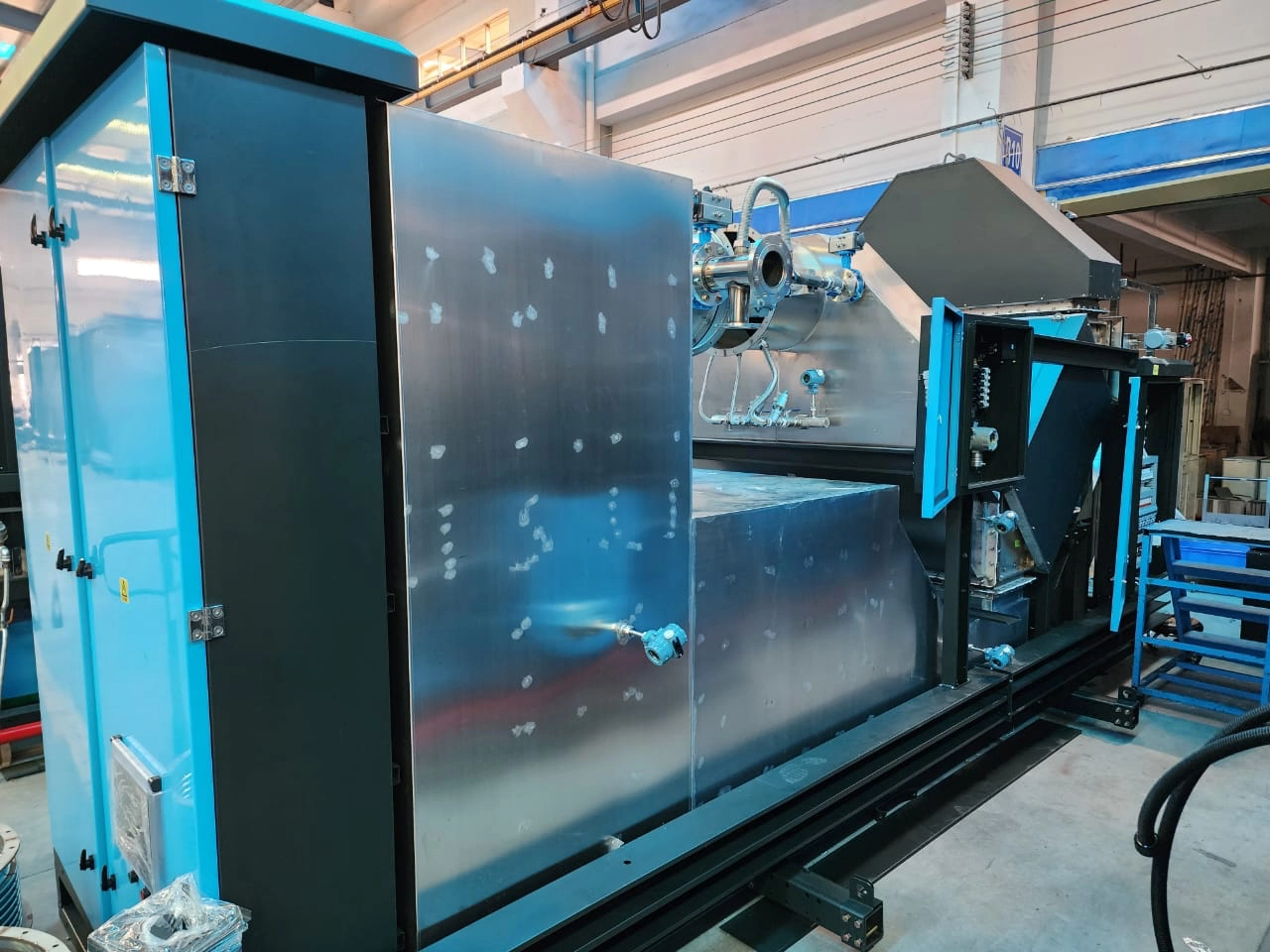

OUR ASSEMBLY LINE

All components of the plasma unit are made of stainless steel and quartz glass, which makes it easy to operate and maintain, it is enough to wash it with the use of special detergents, in manual or automatic mode.